GEDORE grease hydraulic pressure spindle 12 t

Original price

706.-

-

Original price

706.-

Original price

706.-

706.-

-

706.-

Current price

706.-

For controlled and safe removal

Designed for a compressive force of 10 t, 12 t or 15 t

The pressure piece can be replaced with a tip and extended if necessary.

The small pressure spindle is secured against unintentional unscrewing by an anti-rotation device.

Deployment preparation:

1. Before use, check that the pressure spindle is unscrewed far enough from the cap so that the pressure piece is in its starting position in the hydraulic cylinder.

2. Unscrew the cap from the spindle body. First, loosen the threaded stud.

3. Screw the spindle body into the puller's crossbar from below until the spindle body protrudes approximately 60 mm from the crossbar.

4. Screw the cap onto the spindle body until it stops and then secure it by screwing in the threaded stud.

Application and operation: e.g. HSP3

5. Attach the puller and pre-tension the spindle body with a 41 mm wrench.

6. Screw the SW 17 pressure spindle into the cap. The hydraulics are now engaged. The stroke of the pressure piece in the hydraulic cylinder is max. 12 mm. The hydraulically released workpiece can be completely removed by rotating the spindle body with the SW 41 cap.

7. After use, the pressure spindle SW 17 is turned back to its starting position and the pressure piece is pressed into the hydraulic cylinder.

Designed for a compressive force of 10 t, 12 t or 15 t

The pressure piece can be replaced with a tip and extended if necessary.

The small pressure spindle is secured against unintentional unscrewing by an anti-rotation device.

Deployment preparation:

1. Before use, check that the pressure spindle is unscrewed far enough from the cap so that the pressure piece is in its starting position in the hydraulic cylinder.

2. Unscrew the cap from the spindle body. First, loosen the threaded stud.

3. Screw the spindle body into the puller's crossbar from below until the spindle body protrudes approximately 60 mm from the crossbar.

4. Screw the cap onto the spindle body until it stops and then secure it by screwing in the threaded stud.

Application and operation: e.g. HSP3

5. Attach the puller and pre-tension the spindle body with a 41 mm wrench.

6. Screw the SW 17 pressure spindle into the cap. The hydraulics are now engaged. The stroke of the pressure piece in the hydraulic cylinder is max. 12 mm. The hydraulically released workpiece can be completely removed by rotating the spindle body with the SW 41 cap.

7. After use, the pressure spindle SW 17 is turned back to its starting position and the pressure piece is pressed into the hydraulic cylinder.

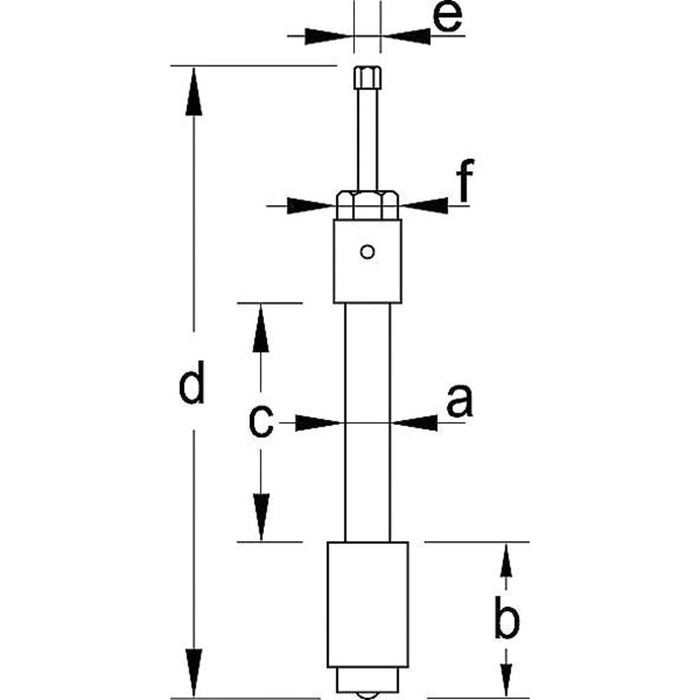

- Compressive force [kN]: 120 kN

- Compressive force [N·m]: 19 N·m

- Compressive force [t]: 12 t

- Pressure piece type: Ball pressure piece

- Total length [mm]: 420 mm

- Stroke: 12 mm

- Contents (number of pieces): 1 pc.

- Head height 1 [mm]: 80 mm

- Net weight [g]: 1800 g

- Net weight [kg]: 1.8 kg

- Usable thread length [mm]: 205 mm

- REACH registration: No

- Wrench size 1 [mm]: 12 mm

- Wrench size 2 [mm]: 36 mm

- Tensioning brackets available: No

- Spindle thread size: G 3/4"

- Reversible arms: No

- Customs tariff number: 82055980

Technical data

| name | Value |

|---|---|

| Total length (mm) | 420 |

| thread | G 3/4" |

| brand | GEDORE |

| type | 1.06/HSP2 |